The ‘03-’07 Ford 6.0L Powerstrokes may have one of the worst reputations of all diesels. If you have ever owned one you have probably experienced some problems; there is a reason their nickname is Six Blow.

Although the issues with the 6.0L are fairly exaggerated, they do still exist. Luckily, fixes are available and once completed you can have a tough and reliable truck!

So what are the most common problems with the 6.0L and how do you fix them?

Head Gaskets:

The most common failure on the 6.0L is a blown head gasket. The reason the gaskets fail is due to the design of the factory head bolts. The factory head bolts can not handle any increases in cylinder head pressures from tunes or modifications. Once the vehicle is modified the head gasket becomes a ticking time bomb with the added pressure.

Easiest way to prevent the head gasket failure is to replace the factory head bolts with upgraded ARP Head Studs. The head studs are slightly longer allowing them to thread completely into the block. This helps spread the load on the head more evenly while increasing the clamping force.

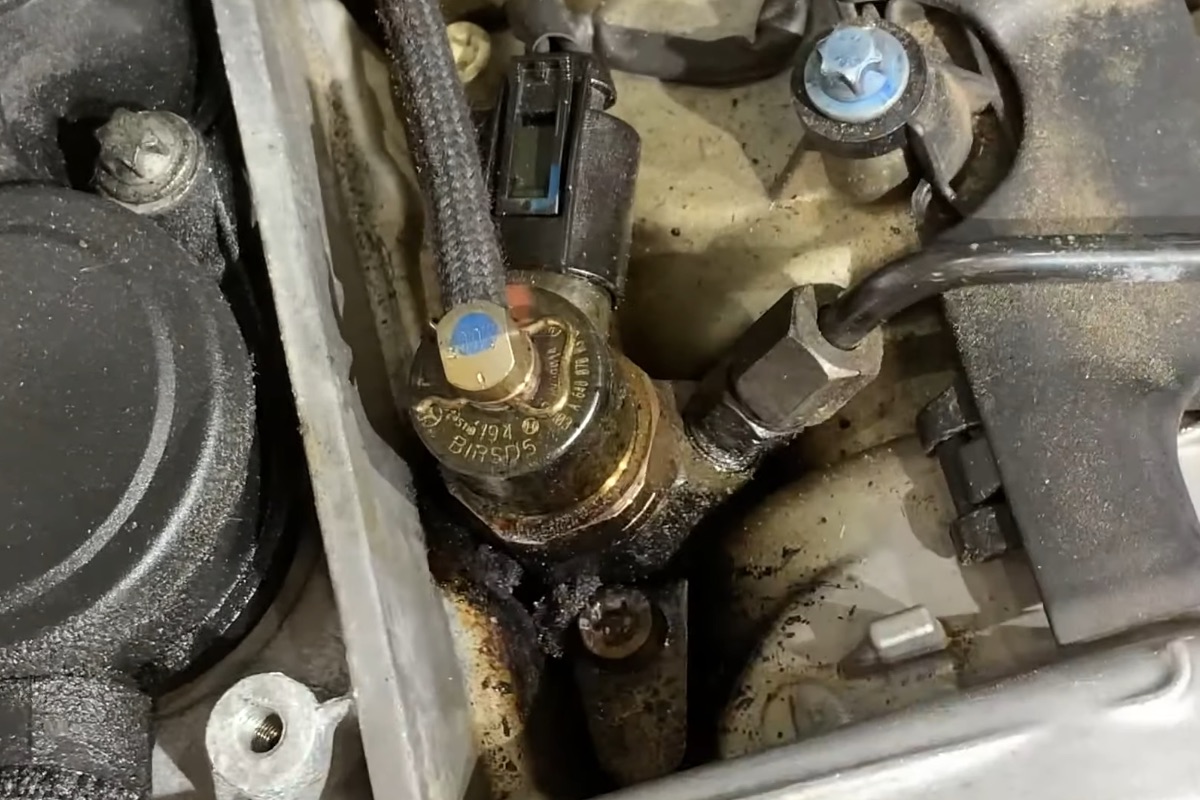

Oil Cooler & EGR:

The 6.0L uses a liquid-on-liquid oil cooler design as the oil must be cooled significantly more than other diesel trucks. A properly operating oil cooler will keep the difference in temperature around 14°F. When the oil cooler fails the coolant side filter typically gets clogged from debris like sand causing the difference in temperature to rise and the truck to overheat. The blocked oil cooler allows less coolant to enter the EGR cooler leading to the EGR failing due to boiling coolant and higher temps. To fix this issue, the filter screen for the oil cooler should be replaced, the oil cooler changed, a new EGR cooler installed, and a full coolant flush. Aftermarket units of the oil cooler and EGRs are built with many improvements to help prevent clogging and failures. We also suggest routinely flushing the coolant to help keep contaminants out of the system.

Fuel Injection Control Module AKA FICM:

The FICM sends 48v to two different solenoids that control the oil flow to the fuel injectors. The problem with the FICM isn’t truly a fault with the module but based on its location in the engine. For some reason, the FICM is located on the side of the valve cover where it is exposed to high temps and excessive vibrations. A failed FICM can cause no starts or rough starts and rough running. Aftermarket FICMs are designed to dissipate heat and absorb vibrations much better than their OE equivalent.

Fixing these common issues and maintaining a strict service schedule with oil and fuel filter changes will allow you to get the most out of the Ford 6.0L Powerstrokes. Once the common issues are handled the 6.0L can become a reliable daily driver or work vehicle.