Maybe you’ve had the experience: Some turbos die with a bang, some with a whimper. The ones that go BANG usually take you by surprise. You’re accelerating onto a highway, passing someone, climbing a hill, maybe driving in a “spirited” fashion, and it blows. A pop, a huge cloud of smoke, and no power.

You coast to the side of the road or the appropriately named breakdown lane and lift the hood. Maybe things look normal, or maybe the turbo shows signs of carnage. Either way, you’re in for a tow and a replacement.

When turbos die with a whimper, you may not know it’s even happened right away. You may get some smoke, maybe not. You notice a loss of power, but maybe nothing else. Eventually you’ll get a CEL. But you may drive the car for a while longer until you can get a diagnosis: the turbo has failed.

Can you prevent turbo failure? Maybe, maybe not. Are there signs of it coming? Often, yes. Let’s list what those might be.

Signs of Failure

It’s true that some turbos fail without warning. But others provide clues that all is not well. Here’s what to look for, or pay attention to:

- Oil loss or consumption: The shaft that supports most turbines (cold and hot) floats on a cushion of oil. If the turbo is failing, lower pressure on one side of the turbine can force oil into the intercooler and piping, or into the engine. Either way, you’ll notice a drop in crankcase oil level.

- Power loss: As a turbo fails, it can lose its ability to make boost. This can happen slowly or quickly. You might notice a sudden loss of power, or you may, over time, feel like your diesel isn’t as quick as usual.

- Whine: This is probably the most obvious sign of failure. If turbo vanes are damaged, the shaft and vane assembly will become unbalanced, and the vanes can strike the compressor housing as they spin. This causes the whine. Usually it’s most noticeable during a high boost request: hard acceleration or climbing hills.

Causes of Failure

Myth bust: Turbos very rarely fail because of a manufacturing defect. By far, the most common reasons for failure are:

- Overspeed: As you’re probably aware, turbo blades spin at very high speeds, up to 100,000 RPM. If caused to spin faster, they can lose balance, blades will strike the housing, and the party is over. This can be caused by a malfunction in the boost management system in your engine, by a faulty tune, or a runaway, where crankcase oil gets into the intake and acts as additional fuel to the engine. When this happens, the engine management cannot control boost because it can’t reduce “fuel” (crankcase oil) and the turbo can overspeed.

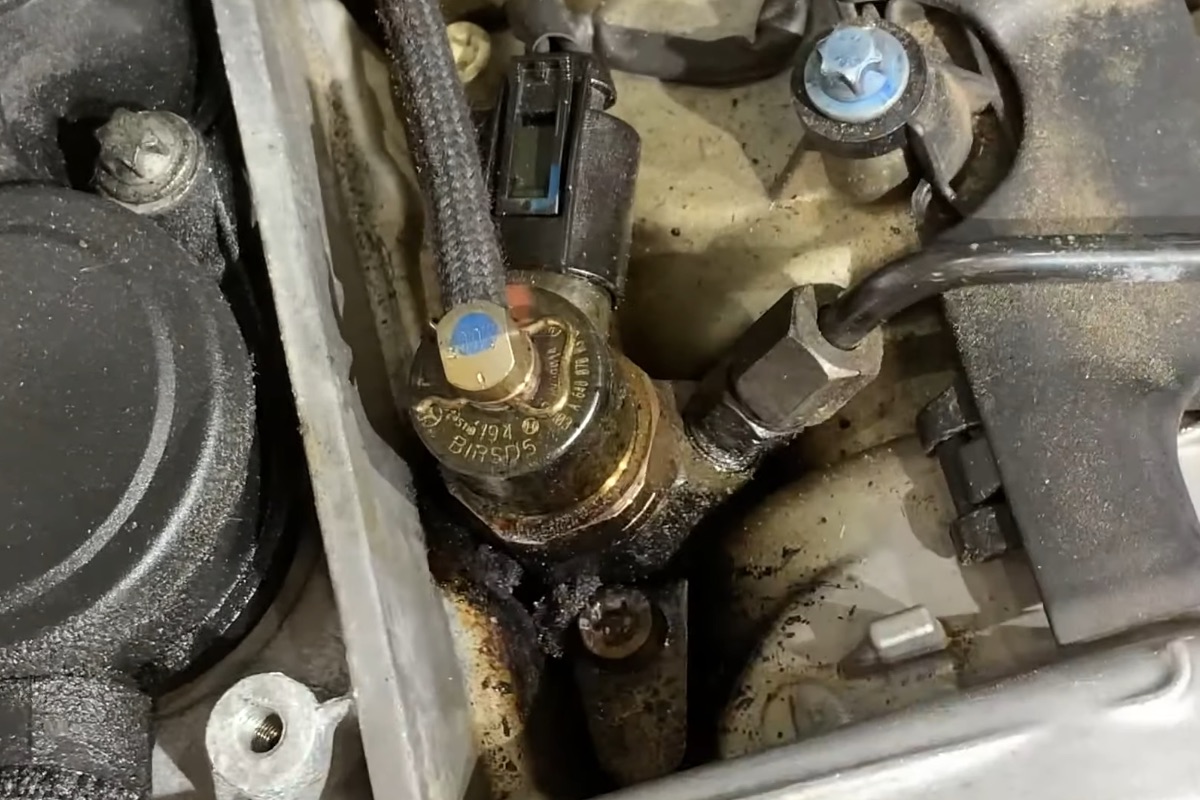

A boost leak can also cause overspeed. If your diesel has a boost leak, the ECU may not see the requested boost because it’s leaking out. It may request more boost from the turbo, causing overspeed. - Oil contamination: Because of their operating speed, turbos require clean oil. If your diesel’s air filtration system is compromised, if you’ve extended an oil change interval, or if your engine oil contains other debris, it can damage the turbine shaft and, once again, cause that assembly to lose balance. You know the rest.

- Foreign object damage: Air for the engine and turbo enters through the air filter. Then it runs through a closed system for intercooling and into the engine intake, and finally out of the combustion chambers and into the turbine. This system is sealed so dirt and debris should not enter. However, sometimes it happens. Also, carbon and soot can accumulate in the intercooler and piping over time, and sometimes can get ingested into the turbo during operation, mostly during high boost request. As you can imagine, this can wreak havoc on the blade assembly.

Other causes are possible, including actuator failure causing overboost, or the less likely machining or assembly error that causes failure.

How to Avoid Turbo Failure

Sometimes you can’t, but there are things you can do to prolong turbo life.

- Oil selection and change intervals: Use oil that includes certifications for your engine, and follow the manufacturer’s maintenance schedule for change intervals. This will go a long way toward prolonging turbo life.

- Air filtration: Make sure your air intake is clean and airflow through the filter is not compromised. A loose airbox cover, damaged filter, or loose airbox to turbo inlet pipe can introduce foreign objects into the turbo system.

- Check intercooler and boost pipes: A loose boost pipe, damaged intercooler, or split hose can both create boost leaks and introduce foreign objects. Keeping this system in good condition will prevent this.

- Monitor crankcase venting: As the engine wears, it can bring more oil into the CCV, and, consequently, into the turbo. This eventually can accumulate and possibly cause a runaway. Also, the CCV can be a source of dirt and debris.

Summary

Diesel turbochargers can easily last hundreds of thousands of miles. Keep your engine and its management system in spec and good condition and yours will, too!