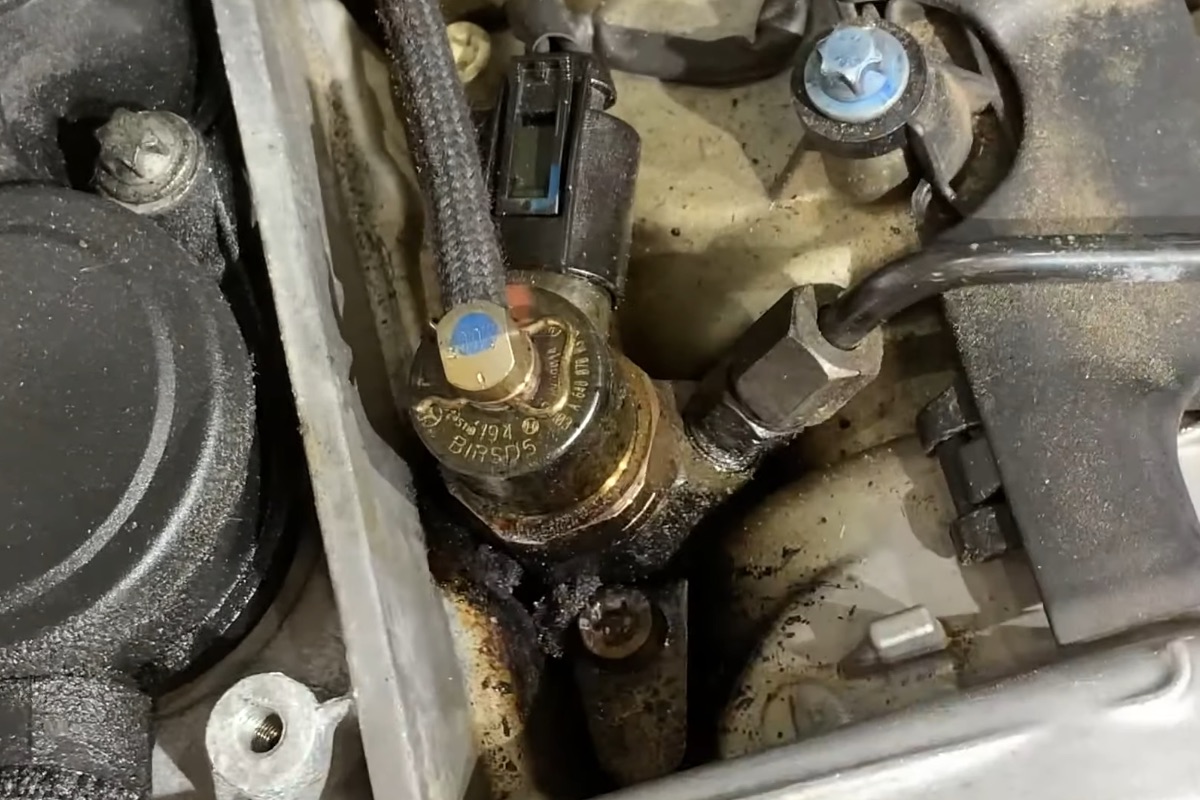

If you’ve heard of injector black death in your Mercedes diesel or Sprinter before but don’t know what it is or how to deal with it, we’ve got you covered! Injector “Black Death” is when the seal under your injector fails. This causes exhaust fumes to leak. When it escapes, it carbonizes and builds up as a gunk in the engine, leading to hard starting and decreased fuel economy. For obvious reasons, this is not good for your vehicle’s engine.

Necessary Parts & Tools

Making sure you have the correct tools is essential to this fix. Here’s what you need:

- Injector Removal Claw: This tool is essential for this job. The valve cover is made of aluminum and using a tool like vice grips can damage the valve cover, which is a costly addition to your repairs.

- Slide Hammer: The slide hammer attaches to the removal claw to back the injector out.

- New Bolt and Seal: One of the most important steps is using a bolt and seal. The bolt is a stretch-to-yield bolt. Using an old bolt will not properly seal the new injector and you’ll be repeating this job before you know it.

Steps

*During all steps: Be mindful of the aluminum cover as to not damage it*

- First, remove the fuel line (14mm wrench), the electrical connector, and the return line.

- Now you can remove the injector hold down bolt with a T40 torx bit.

- Use a penetrating spray such as PB Blaster to loosen some of the black deposits around the hold down claw.

- Do not pry against the cover to try to loosen the hold down claw. If necessary, you can use a flathead screwdriver between the claw and the injector to try to gently hand pry it loose. A hand pick tool will help pull the claw out.

- Use the hand pick tool to loosen some of the gunk after getting the claw out.

- Place the removal claw around the injector so that it is fully seated. You will need to work it into place and may need to keep scraping more deposits out.

- Thread your slide hammer into the top hole of the claw and work the injector out. If the seal gets stuck, use your pick tool to pull it out. Always double-check to make sure the seal isn’t still inside.

- *TIP* If you are having trouble getting the injector out, you can use a heat gun, not a torch, to heat the injector to around 180-200°. This will soften some of that “black death”.

- Cleaning out the injector bore and surrounding area will take some time. Use brake and parts cleaner. Since it is not water-based, it will evaporate and not rust any engine components. Also get a brass brush: Brass is a softer metal than aluminum, and this will help prevent damage to the aluminum cover.

- Once you’ve cleaned it out, we recommend using a shop vac extension adapter. You can use these narrow-ended extensions to get a hose directly into the injector bore to clean out any remaining deposits loosened with the brush.

- Now it is time to reassemble. Make sure you’re using a new bolt; it is a 3-stage torque. Torque to 7nm and 2 90° turns and don’t even think about re-using the old bolt!

Now you are all set and ready to get your vehicle back in working order. Diesel on!